If there is one thing that (almost) everyone agrees on, it is that Iberian ham is the jewel of Spanish gastronomy . Its balanced but intense flavour, its palatability and smoothness, the explosion it causes on the palate when you eat it are all examples of the wonderful culinary art of our land.

What perhaps not everyone knows is the process that Iberian ham and shoulder have to go through to achieve all those characteristics that make it so special.

Firstly, it will depend on the type of breed of pig and its percentage (100%, 75%, 50% Iberian or white) and the diet it has had during the montanera (acorns and other resources from the pasture, artificial feed or a mixture of both), but also on the production process .

Let's start from the beginning

Iberian ham comes from the hind legs of the animals, while the shoulders come from the front legs, which are slightly smaller. At Don Ibérico we carefully select the best pigs to achieve the best final product.

In the case of ham, we are dealing with a larger piece than the shoulder, both in length, width and weight. Both are characterised by their black hoof and narrow shank. When cut, they have streaks of fat and, perhaps, some small white spots known as tyrosine crystals , which are nothing more than a sign that the piece has been cured slowly and carefully.

The process of elaboration

Salting

Once the best pigs have been selected and the hams have been received at the factory, it is time to classify them according to their weight . In this way, during the salting of the pieces, the perfect conservation of the portions will be achieved through partial dehydration, obtaining protection against bacteria and reinforcing their flavour.

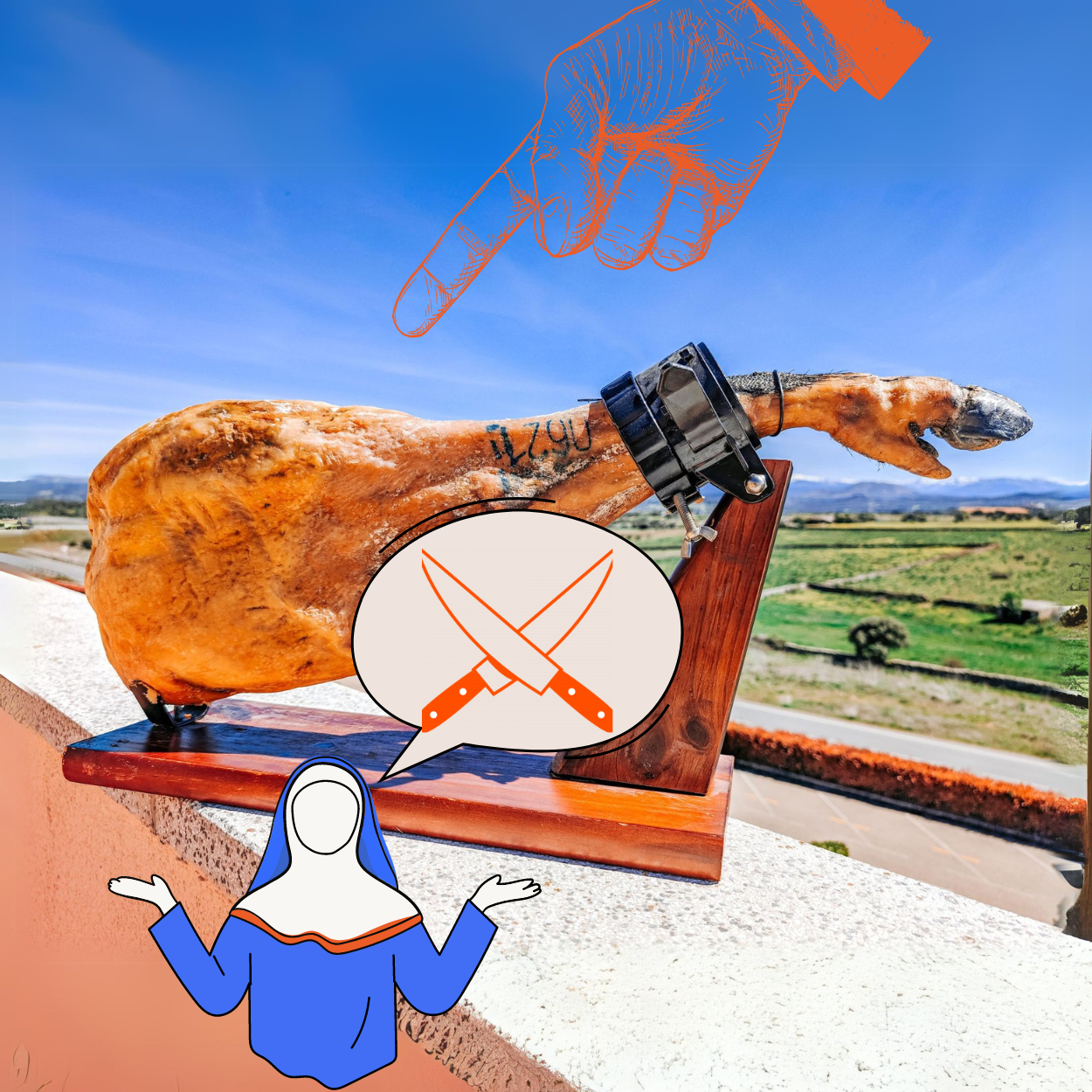

The hams and shoulders are covered in salt and kept for a few days, as determined by the master craftsman based on the flavour he wants to achieve in the piece. Sometimes, a "V" cut is also made to allow the salt to penetrate even further into the piece.

On average, the pieces are buried in salt for one day per kilo (although there are exceptions from time to time). The more days they are buried, the saltier the final product will be. During these days, the process is controlled by the master ham makers, who ensure that it is done and maintained correctly.

Once the day has arrived, it is time for the bath. The hams and shoulders are washed with warm water to remove the salt that has not penetrated and they are shaped, profiled and refined so that they take the shape that we already know after having been stacked on top of each other.

Seated (Rest)

The second stage of the production of Iberian ham and Iberian shoulders is the rest period. During the winter, the pieces spend the winter in natural drying rooms , which are cold and spacious spaces with windows. There, the hams and shoulders remain in semi-darkness and the artisans open and close the windows daily to control ventilation and maintain optimal humidity and temperature conditions.

The long, cold and dry winters that characterize the Salamanca region help the pieces to achieve the perfect balance and to gradually prepare themselves for the intense (and short) summer.

Drying and maturation

With the arrival of spring and the rise in temperatures, drying and maturation begins. As the heat in the drying rooms increases, the pieces become dehydrated. This process is known as "sweating" the ham . It is an essential stage in achieving a quality ham and shoulder.

During the drying time, the fat is distributed evenly, giving the characteristic white streaks. It is at this point that the characteristic flavour begins to form .

Aging in the cellar

When the drying and maturing stage is over, they are classified again according to their weight and fat content. They are then taken to the cellars, where they will remain for a longer or shorter period depending on their weight. At Don Ibérico, the shoulders are never kept for less than 24 months, nor the hams for less than 36 months.

The factory's cellars are very large, quiet spaces where little light enters. There, the humidity remains constant between 60 and 80%, as does the temperature, which is between 10 and 14 degrees.

At the end of this stage, the "puncturing" or "cala" is carried out. This technique consists of making three incisions on one side of the ham or shoulder with a needle made of bone. This serves to check the characteristics and quality of the ham and shoulder.

An artisanal process that makes the difference

The process of making hams and shoulders can last several years. It may seem like a long time, but it is essential to achieve the highest quality and achieve that characteristic flavour that we like so much.

At Don Ibérico we are experts in artisanal production, in doing things without rushing. It is one of the pillars of our family and it is, without a doubt, the best way to conquer all palates.

NEW

PACKS DON'T BE SCARED